Heat Exchangers 101: Grasping Their Significance in Industrial Applications

Heat exchangers play a crucial role in a variety of industries, serving as key components that facilitate the transfer of heat between multiple liquids. Whether it is in production, power generation, or HVAC systems, these components are critical for improving energy efficiency and guaranteeing optimal operations. Understanding how heat exchangers function and their different kinds can significantly improve our understanding of their significance in both industrial use and daily life.

In this article, we will explore the various kinds of heat exchangers, explore their applications across various sectors, and highlight the importance of regular maintenance to prevent performance issues. Starting with the classic shell and tube designs to innovative compact models, we will also discuss factors to take into account when selecting the right heat exchanger for your specific needs. As we anticipate the future, it is essential to acknowledge the ongoing advancements in heat exchanger technology and how they contribute to sustainability efforts in an increasingly energy-conscious world.

Categories and Uses of Heat Exchangers

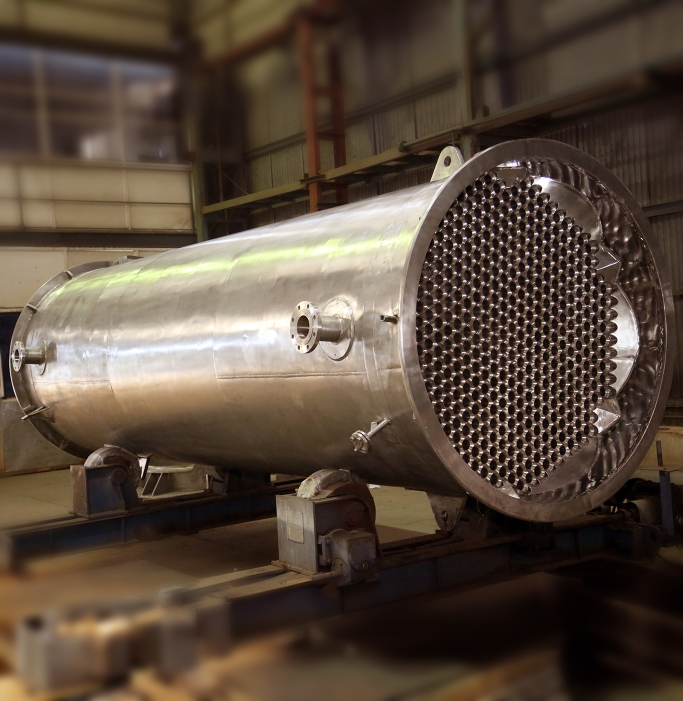

Thermal exchangers are key elements in a variety of commercial applications. The most common kinds of heat exchangers include shell and tube heat exchangers, plate exchangers, and air-cooled exchangers. StandardXchange -and-tube exchangers consist of a set of cylinders, one set carrying the heated fluid and the second the cool fluid, allowing for efficient heat transfer between them. Plate exchangers, on the contrary, use multiple flat sheets to create channels through which fluids flow, providing a greater surface area for heat transfer in a concise design. Air-cooled exchangers leverage surrounding air to cool fluids, making them perfect for uses where water is scarce.

In the chemical industry, heat exchangers are essential for operations such as distillation, where they assist in the transfer of heat to maintain ideal temperatures for chemical processes. Similarly, in power plants, thermal exchangers play a key role in transforming the heat generated from burning fuel into electricity. Their applications extend to food and drink production, where maintaining certain temperature parameters is essential for security and quality.

The versatility of thermal exchangers also makes them essential in HVAC systems, where they control heat and ensure satisfaction in buildings. In sustainable energy systems, heat exchangers help capture and transfer energy from sources like solar energy and geothermal. As sectors evolve, the development of tailored heat exchangers customized to meet specific operational needs continues to broaden their applications across different industries.

Energy Conservation and Maintenance

Heat transfer devices play a pivotal role in improving energy use across diverse industrial processes. By shifting thermal energy between liquids, they reduce the need for further heating or cooling, which can minimally cut down power use. In various contexts, enhancing the thermal exchange method can lead to substantial financial benefits and lower environmental footprint, making these systems crucial for sectors dedicated to sustainable practices.

Regular maintenance of heat transfer devices is essential to make sure they function at optimal effectiveness. Fouling, a typical challenge caused by the accumulation of undesirable elements on thermal conductors, can reduce efficiency and lead to higher energy consumption. Routine check-ups and cleaning can prevent these reductions in performance and extend the duration of the infrastructure. Adopting automated systems can also aid in identifying efficiency loss quickly, allowing for timely maintenance interventions.

Furthermore, picking the suitable materials, such as durable metals for its resilience, can boost the longevity and performance of thermal exchangers. Understanding the specific requirements of each application will assist in selecting the best configuration and service approach. With the right approach, companies can enhance fuel savings, limit idle time, and boost the total effectiveness of their operations.

Innovations and Upcoming Developments

The heat exchanger industry is experiencing significant advancements aimed at boosting performance, productivity. Advanced materials such as polymer composites and innovative alloys are being investigated to improve heat transfer capabilities while minimizing decay and contamination. Additionally, the adoption of intelligent technologies, such as IoT sensors, is changing how heat exchangers are monitored and maintained, permitting operators to gather real-time data and optimize performance in real-time.

Another movement is the development of compact and modular heat exchangers, which are engineered to nestle in tight spots while providing high output. These concepts cater to industries where space is at a premium, such as in electric vehicles and renewable energy systems. Advances in additive manufacturing (3D printing) are also creating the way for complex designs that can improve thermal performance and minimize material waste, making production more sustainable.

Finally, sustainability is becoming a key priority for heat exchanger development. The drive towards more sustainable technologies is leading to the development of heat exchangers that facilitate energy recovery and minimize overall carbon footprints. As businesses and industries commit to reducing energy use and emissions, the prospects of heat exchanger technology will likely focus on eco-friendly operations, with an emphasis on life cycle analysis and recyclability of materials used in their manufacture.